We at A.C.T. are thermoforming experts specializing on integrating infrared technology into the thermoforming process. We have installed ovens in rotary, twin sheet, shuttle and roll fed machines. Ovens are completely zonable with zones ranging in size from 12″ x 12″ up to 2′ x 6′, with many sizes in between.

Both gas catalytic and electric IR panel heaters offer improvements over inefficient resistance elements like calrods or nichrome wire. After an IR retrofit, you can expect:

- energy savings

- shorter cycle times

- better part quality

- greater repeatability

- lower scrap rates

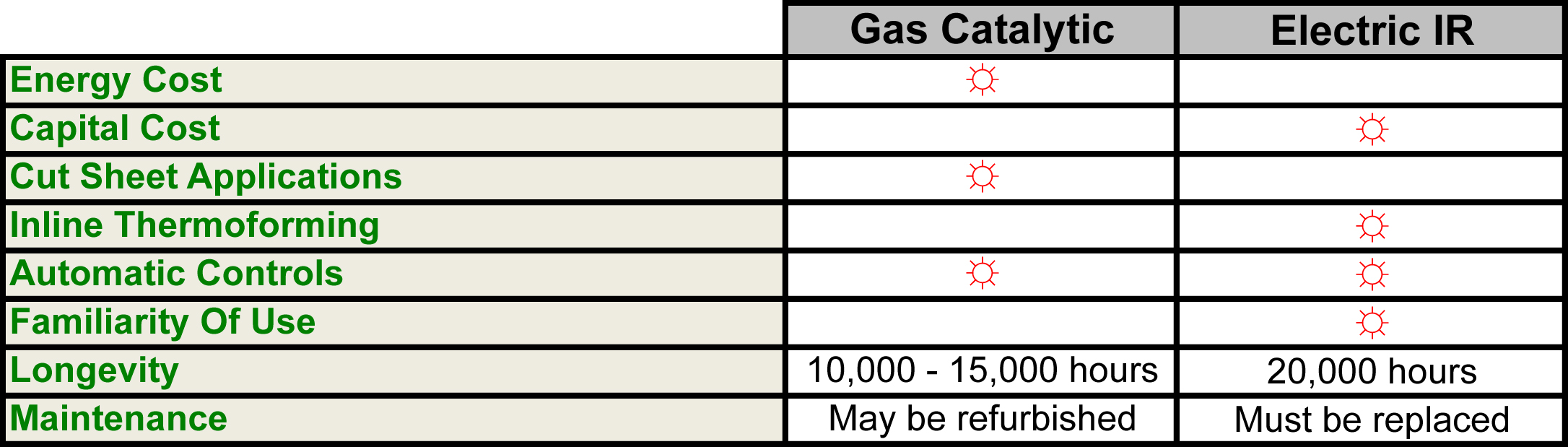

Catalytic Option

Catalytic heaters are the emitter of choice when energy costs are a concern. In the U.S., natural gas costs between 1.0 and 1.5 cents per kW compared to electricity which varies between 8 and 20 cents per kW (including demand charges) depending on the state. Generally, they cost 80% less to operate than electric heaters and a complete retrofit will pay for itself in one to two years. We prepare an energy savings analysis of a prospective retrofit, so you may see up front what your projected savings and R.O.I. would be.

Catalytic heaters are most effective in cut sheet applications, especially with medium to heavy gauge plastics, including high molecular weight materials. They are well suited for many products which include, but are not limited to:

- instrument cases

- plastic dunnage

- spas

- pickup bed liners

- auto and aircraft trim

- shower stalls

- outdoor toilet systems

- retail display cases

Ovens are zoned and can be controlled manually using ball valves, or pulse controls: an automated system that oscillate gas flow between low and high fire over a timed interval to achieve the desired heat profile.

Electric Option

Our IR electric heaters, while more costly to operate have a lower capital cost than the gas option. Although the difference is recovered over time, the lower up front cost may be of greater value when short term cash flow is a consideration.

From a process standpoint, we recommend electric emitters for inline thermoforming applications, as well as applications which require tight zoning. Also, there is great familiarity with electric ovens, and that provides for shorter learning curves in retrofit scenarios. Zones are controlled either on a percentage timer basis or using a closed loop system to maintain set temperatures.

The following table summarizes the pros and cons of both emitter options.

There are many factors to consider when choosing an infrared oven. Let us work with you to help you decide which is the best option for your process.